Comprehensive repair manuals, like those from Clymer, offer detailed guides for over 25 years of engine models, covering 90,000+ repairs with PDF access.

What is a Small Engine?

Small engines generally refer to internal combustion engines, typically with less than 25 horsepower, powering equipment like lawnmowers, snowblowers, and generators. Repair manuals, such as those found in the Small Engine Repair Reference Center, detail these engines’ components. These guides cover routine maintenance and complex projects for major brands. Understanding their mechanics, aided by detailed repair information, is crucial for effective troubleshooting and upkeep, ensuring longevity and optimal performance of your outdoor power equipment.

Why Repair Instead of Replace?

Utilizing a small engine repair manual often proves more economical than outright replacement. Many issues, detailed in repair guides like Clymer manuals, involve relatively inexpensive parts – spark plugs, air filters, or carburetor components. The Small Engine Repair Reference Center offers access to over 90,000 repairs. Repairing extends equipment life, reduces landfill waste, and fosters self-sufficiency, making it a sustainable and cost-effective alternative.

Essential Tools for Small Engine Repair

Repair manuals highlight the need for basic hand tools alongside specialized equipment, ensuring successful diagnosis and execution of engine maintenance procedures.

Basic Hand Tools

Small engine repair manuals consistently emphasize a foundational set of hand tools. This includes socket wrenches, screwdrivers (Phillips and flathead), pliers, adjustable wrenches, and a torque wrench for precise tightening. A good set of feeler gauges is crucial for valve adjustments, as detailed in many repair guides. Having penetrating oil, scrapers, and punches readily available will also significantly aid in disassembly and cleaning processes, streamlining the repair work.

Specialized Tools

Small engine repair manuals often highlight the need for tools beyond the basic set. A compression tester is vital for diagnosing engine health, while a timing light ensures correct ignition timing. Valve lapping tools are essential for proper valve seating, as described in detailed repair guides. Cylinder hone and ring compressor tools are needed for piston and ring work, ensuring optimal engine performance and longevity during complex repairs.

Safety Equipment

Small engine repair manuals consistently emphasize safety as paramount. Always wear safety glasses to protect your eyes from debris. Repair guides recommend using gloves to shield hands from chemicals and sharp edges. A well-ventilated workspace is crucial when dealing with fuels and exhaust. Proper clothing, avoiding loose fits, prevents entanglement with moving parts, ensuring a safe repair process as detailed in comprehensive manuals.

Understanding Small Engine Components

Repair manuals detail the engine block, carburetor function, and ignition system – essential knowledge for diagnosing issues and performing effective repairs.

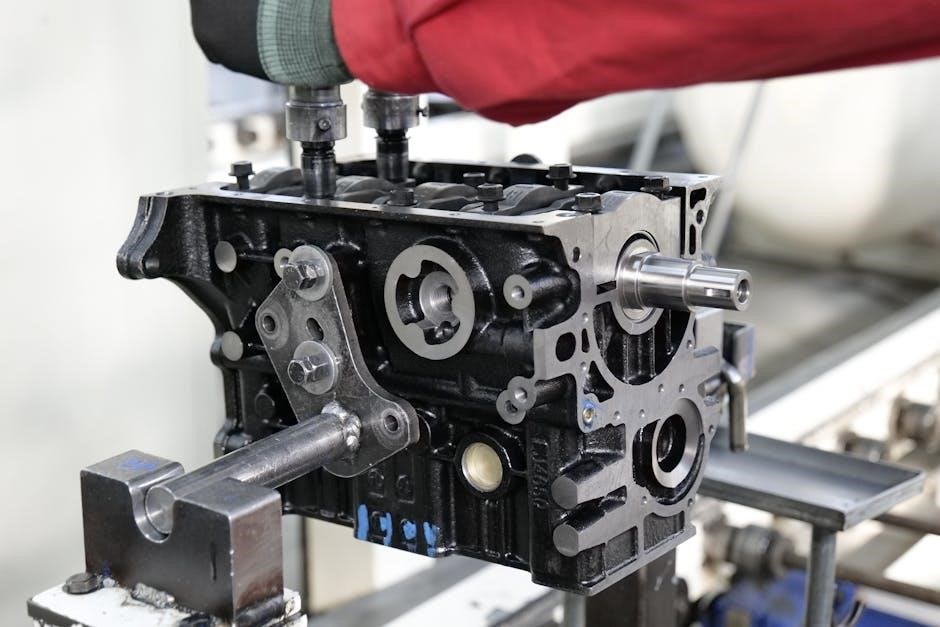

The Engine Block

Repair manuals emphasize the engine block as the foundational component, detailing procedures like cleaning carbon buildup from cylinder head or pot surfaces. They guide users through inspecting for, and addressing, issues such as worn crankcase seals. Manuals illustrate proper tightening of connecting rod bolts, and offer guidance on cylinder repair or complete replacement when necessary, ensuring structural integrity and optimal performance.

Carburetor Function

Repair manuals dedicate significant sections to carburetor maintenance, outlining cleaning procedures to restore proper fuel delivery. They detail how to diagnose and rectify issues affecting the fuel-air mixture, crucial for efficient combustion. Guides explain the importance of a correctly functioning carburetor for optimal engine performance, covering adjustments and potential repair steps for various models.

Ignition System Overview

Small engine repair manuals thoroughly cover the ignition system, detailing components like the ignition coil and recoil starter. Guides explain testing procedures for the coil to ensure proper spark generation. Diagrams aid in interpreting wiring, crucial for troubleshooting starting issues. Repair instructions detail recoil starter replacement, vital for manual starting functionality.

Common Small Engine Problems & Diagnosis

Repair manuals pinpoint issues like starting failures, rough running, and power loss, offering diagnostic steps and repair procedures for each symptom.

Engine Won’t Start

Repair manuals systematically address no-start conditions, guiding users through checks of the fuel system – tank, lines, and pump – and the ignition system, including coil testing. They detail procedures for verifying spark, confirming fuel delivery, and diagnosing carburetor issues. Manuals also cover inspecting crankcase seals and magneto timing, essential for successful restarts, offering clear steps for troubleshooting and resolution, ensuring a comprehensive diagnostic approach.

Engine Runs Rough

Repair manuals pinpoint rough running as often stemming from carburetor problems or carbon buildup. They instruct on thorough carburetor cleaning and inspection, alongside cylinder head decarbonization. Guides detail checking and potentially replacing worn components like connecting rods or crankshafts. Manuals emphasize proper timing and tightening procedures, ensuring optimal combustion and smooth engine operation, offering detailed steps for diagnosis and correction.

Loss of Power

Repair manuals address power loss by focusing on fuel systems and compression. They guide users through inspecting fuel tanks, lines, and pumps for obstructions or failures. Detailed instructions cover cylinder and piston assessments, including ring replacement if necessary. Manuals emphasize magneto timing and proper cylinder head sealing to maintain optimal compression, restoring the engine’s original power output through systematic troubleshooting.

Step-by-Step Repair Procedures

Repair manuals provide visually engaging, step-by-step instructions for tasks like carburetor cleaning, spark plug replacement, and air filter maintenance for optimal performance.

Carburetor Cleaning and Repair

Detailed repair manuals guide users through dismantling carburetors, identifying worn components, and meticulously cleaning jets and passages to restore proper fuel delivery. They illustrate techniques for replacing gaskets, adjusting fuel mixture screws, and reassembling the carburetor correctly. PDF guides often include diagrams showing exploded views, aiding in accurate reassembly. Addressing carbon buildup and ensuring all parts are spotless is crucial for smooth engine operation, as outlined in comprehensive repair references.

Spark Plug Replacement

Repair manuals provide step-by-step instructions for spark plug replacement, including gap specification charts for various engine models. They detail proper removal techniques to avoid damaging the cylinder head threads. Guides illustrate identifying fouled spark plugs and diagnosing ignition issues. PDF resources emphasize using the correct torque when installing new plugs, ensuring a secure connection and optimal engine performance, as detailed in comprehensive repair documentation.

Air Filter Maintenance

Repair manuals thoroughly cover air filter maintenance, detailing inspection intervals and cleaning procedures for foam and paper elements. They illustrate proper oiling techniques for foam filters, crucial for effective dust capture. PDF guides emphasize replacing filters regularly to maintain optimal airflow and prevent engine damage. Detailed diagrams show filter housing locations and removal steps, ensuring proper engine operation as outlined in comprehensive repair documentation.

Advanced Repair Techniques

Repair manuals detail complex procedures like valve adjustments, cylinder head work, and piston/ring replacement, offering step-by-step guides and diagrams.

Valve Adjustment

Small engine repair manuals emphasize precise valve clearances for optimal performance. They guide users through checking and adjusting valve lash using feeler gauges, ensuring proper engine timing and compression. Detailed diagrams illustrate the valve train components and adjustment procedures. Incorrect valve settings can lead to reduced power, overheating, and even engine damage, making accurate adjustment crucial. Manuals provide specific clearance specifications for various engine models, enabling technicians to restore factory settings and maintain engine efficiency.

Cylinder Head Repair

Small engine repair manuals detail cylinder head inspection and repair procedures. They cover carbon removal from head surfaces, a common maintenance task, and guide users through checking for cracks or warping. Manuals illustrate proper torque specifications for head bolts, crucial for maintaining a tight seal. Repair often involves gasket replacement and valve seat grinding, ensuring optimal compression. Detailed diagrams aid in disassembly and reassembly, preventing damage and restoring engine performance.

Piston and Ring Replacement

Small engine repair manuals provide step-by-step instructions for piston and ring replacement, a more complex repair. They detail proper piston removal techniques and emphasize the importance of cylinder bore inspection for wear. Manuals guide users through ring gap measurement and installation, ensuring a proper seal. Repair includes crankshaft inspection and connecting rod bolt tightening, with diagrams illustrating correct procedures for optimal engine function and longevity.

Fuel Systems and Troubleshooting

Repair manuals detail fuel tank draining, line inspection, and pump repair, alongside guidance on correct fuel/oil mixture ratios for optimal performance.

Fuel Tank and Lines

Small engine repair manuals emphasize thoroughly draining the fuel tank before any maintenance, ensuring safety and preventing issues. They guide users to inspect fuel lines for cracks, leaks, or deterioration, recommending replacement when necessary. Proper fuel line connections are crucial; manuals illustrate correct routing and clamping techniques.

Detailed diagrams show fuel filter locations and replacement procedures, vital for preventing carburetor clogging. Repair guides also cover cleaning sediment from the tank and verifying vent functionality for optimal fuel flow.

Fuel Pump Repair

Small engine repair manuals detail fuel pump disassembly, highlighting the importance of clean work surfaces to avoid contamination. They provide step-by-step instructions for inspecting diaphragms and seals for wear or damage, often recommending complete fuel pump kits for reliable repair.

Repair guides illustrate proper reassembly, emphasizing correct gasket placement and torque specifications. Testing fuel pump output is covered, ensuring adequate fuel delivery to the carburetor for optimal engine performance.

Fuel Mixture Ratios

Small engine repair manuals consistently emphasize the critical nature of correct fuel-to-oil ratios for two-stroke engines, preventing damage from insufficient lubrication or overly rich mixtures. Guides detail specific ratios based on engine model and oil type, often referencing manufacturer recommendations.

Repair resources explain how improper ratios lead to piston seizure or carbon buildup, impacting performance. They also cover adjustments for varying altitudes and operating conditions, ensuring optimal combustion.

Oil Systems and Maintenance

Repair manuals detail oil change procedures, filter replacements, and level checks, vital for maintaining small engine longevity and optimal performance, preventing costly issues.

Oil Change Procedures

Small engine repair manuals emphasize draining the tank before refilling with the recommended fuel/oil mixture as a crucial step. Detailed guides illustrate proper oil change techniques, ensuring optimal lubrication and engine health. These resources often include specific instructions for various engine models, covering oil filter replacement and verifying correct oil levels. Following these procedures, as outlined in comprehensive repair guides, extends engine life and prevents premature wear, ultimately saving on future repair costs and maintaining peak performance.

Oil Filter Replacement

Small engine repair manuals consistently highlight the importance of oil filter replacement during routine maintenance. These guides provide step-by-step instructions, often with detailed diagrams, for accessing and replacing the filter correctly. Proper replacement, as detailed in comprehensive repair resources, ensures clean oil circulation, protecting the engine from abrasive particles. Following these procedures, found within repair references, contributes to extended engine life and optimal performance, preventing costly repairs down the line.

Checking Oil Levels

Small engine repair manuals emphasize regular oil level checks as a crucial preventative measure. These guides detail how to accurately assess the oil, often using a dipstick, before each use and after specific intervals. Maintaining the correct oil level, as illustrated in repair references, prevents engine damage from insufficient lubrication. Following these simple checks, detailed in comprehensive repair resources, ensures optimal performance and extends the engine’s lifespan, avoiding potential costly repairs.

Electrical System Repair

Repair manuals provide wiring diagram interpretation and guides for testing the ignition coil, alongside instructions for recoil starter replacement procedures.

Testing the Ignition Coil

Repair manuals detail procedures for accurately testing the ignition coil’s functionality, a crucial step in diagnosing starting problems. This often involves utilizing a multimeter to check for primary and secondary resistance, comparing readings against manufacturer specifications. A faulty coil prevents spark, hindering engine operation. Guides illustrate how to safely disconnect and test the coil, ensuring proper voltage output. Understanding these tests, as outlined in comprehensive repair resources, empowers effective troubleshooting and component replacement, restoring reliable ignition.

Wiring Diagram Interpretation

Small engine repair manuals emphasize the importance of mastering wiring diagram interpretation for successful electrical system repairs. These diagrams visually represent the connections between components, aiding in tracing faults and identifying shorts or open circuits. Guides explain common symbols and color codes, enabling accurate diagnosis. Understanding these schematics, detailed in repair resources, is vital for safely and effectively resolving electrical issues, restoring proper engine function and preventing further damage.

Replacing the Recoil Starter

Small engine repair manuals provide step-by-step instructions for recoil starter replacement, a common fix detailed in comprehensive guides. The process involves removing the flywheel cover, disconnecting the starter rope, and carefully extracting the old unit. Repair resources illustrate proper alignment and securing of the new starter, ensuring smooth engine starting. Following these manuals guarantees correct installation, preventing damage and restoring reliable operation.

Resources for Repair Manuals & Information

Clymer manuals and the Small Engine Repair Reference Center offer 450+ full-text guides, covering 90,000+ repairs and 25+ years of models.

Clymer Repair Manuals

Clymer Repair Manuals represent a cornerstone resource for small engine enthusiasts and professionals alike. These manuals provide exceptionally detailed, step-by-step instructions, accompanied by original photographs and illustrations, ensuring clarity throughout the repair process.

The collection boasts comprehensive coverage of a vast range of engine models, spanning more than 25 years of manufacturing. Regularly updated with new content, Clymer manuals are accessible through the Small Engine Repair Reference Center, offering PDF full-text access to all documents.

Small Engine Repair Reference Center

The Small Engine Repair Reference Center is a powerful digital resource, containing repair guides for both routine maintenance and complex projects across all major brands and models. It houses over 450 full-text reference books, offering detailed information and visual aids for effective troubleshooting.

Users can search by product type, brand, model, or engine type, accessing a database covering more than 90,000 individual repairs, including the complete collection of Clymer Repair Manuals in convenient PDF format.

Online Forums and Communities

Engaging with online forums and communities dedicated to small engine repair provides a valuable platform for knowledge sharing and problem-solving. These spaces allow enthusiasts and experienced mechanics to exchange advice, discuss repair procedures, and offer assistance with specific engine issues.

Accessing these resources complements traditional repair manuals, offering real-world insights and alternative solutions, fostering a collaborative learning environment for all skill levels.

Preventative Maintenance

Repair manuals emphasize regular inspections and seasonal storage practices to maximize engine life and minimize future complex repairs and downtime.

Regular Inspections

Small engine repair manuals consistently highlight the importance of frequent, thorough inspections as a cornerstone of preventative maintenance. These inspections should encompass checking for loose connections, fuel leaks, and worn or damaged parts. Guides detail visual assessments of belts, hoses, and wiring, alongside functional tests of controls.

Proactive identification of minor issues—like a slightly loose bolt—can prevent escalation into major, costly repairs. Consistent adherence to inspection schedules, as outlined in repair references, significantly extends engine lifespan.

Seasonal Storage

Small engine repair manuals emphasize proper seasonal storage to prevent deterioration during inactivity. Guides recommend stabilizing fuel or draining the tank and carburetor to avoid gumming and corrosion. Repair references detail the importance of changing the oil before storage, protecting internal engine components.

Additionally, manuals advise covering the engine to shield it from dust and moisture. Following these steps, as detailed in comprehensive repair documentation, ensures easier starting and prolonged engine life.

Proper Fuel Storage

Small engine repair manuals consistently highlight the dangers of improper fuel storage, advocating for stabilized fuel or complete draining. Guides detail using fuel stabilizers to prevent degradation during extended periods, crucial for maintaining optimal engine performance. Repair documentation stresses storing fuel in approved, tightly sealed containers.

Manuals caution against storing fuel near heat sources or open flames, emphasizing safety. Following these repair-focused recommendations ensures fuel remains usable and minimizes fire hazards.

Troubleshooting Charts

Repair manuals provide charts diagnosing starting, performance, and overheating issues, streamlining the repair process with clear symptom-solution pathways for small engines.

Starting Problems

Small engine repair manuals dedicate significant sections to diagnosing starting failures, a common issue. Charts detail checks for fuel supply – tank, lines, and pump functionality – alongside ignition system assessments, including the coil and spark plug.

They guide users through verifying compression and carburetor operation, offering step-by-step procedures to pinpoint the root cause. Manuals often include diagrams illustrating potential faults and recommended solutions, ensuring a systematic approach to resolving starting difficulties.

Performance Issues

Small engine repair manuals thoroughly address performance declines, such as rough running or power loss. They detail carburetor troubleshooting – cleaning jets and adjusting mixtures – alongside valve adjustment procedures to ensure optimal engine breathing.

Manuals guide users in inspecting cylinder heads for carbon buildup and assessing piston/ring wear. Diagrams illustrate proper timing and component interactions, aiding in accurate diagnosis and effective repair to restore peak performance.

Overheating

Small engine repair manuals provide systematic approaches to diagnosing overheating issues. They detail checking for clogged cooling fins, malfunctioning thermostats, and proper coolant levels (if applicable). Manuals guide inspection of the cylinder head and block for damage, alongside procedures for replacing worn gaskets.

Illustrated diagrams aid in understanding the cooling system’s components and their interactions, ensuring accurate repair and preventing future overheating incidents, restoring reliable engine operation.